Crafts /

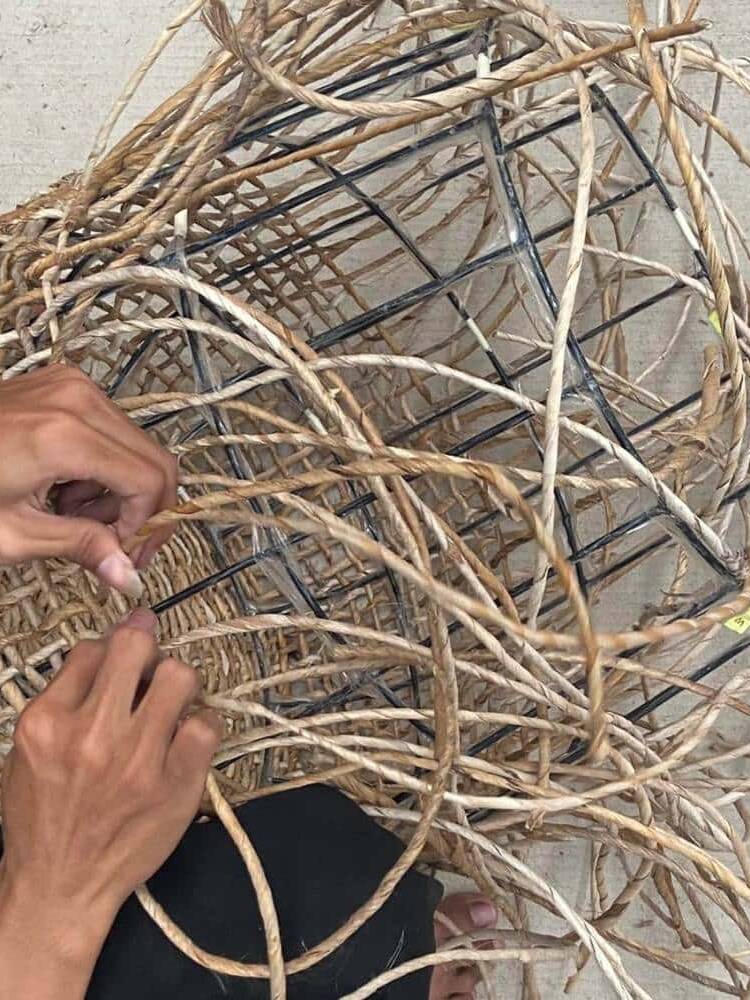

Fabric Weaving

All fabrics in the originalhome collection are woven by hand on a traditional handloom. The handloom workshops in Bangladesh and Indonesia are one of the few that are still operational. Almost everywhere around the world the traditional handloom is replaced by the power loom (machine loom).

Spinning and dying

70% of our textiles are made from handspun yarn. The raw material, waste cotton, is collected from a variety of factories and spun into yarn on a traditional spinning wheel. The spinning wheel is very easy to make and almost everyone can operate it. Often it is operated by women from their own homes when they have time between their home duties. The handspun yarn is dyed with azo free dye by hand and hangout to dry in hanks in the sun before further processing.

Bobbin winding, warp and weft

The dyed yarn hank gets converted into a linear thread form and wound on a bobbin. This process enables laying out of yarn lengths for weaving. Next step is the winding of the warp yarn to the warp beam. During this process the colours, grouping and dimensions of the fabric is determined. The warp represent the vertical part of the weaving pattern. The yarn for the horizontal part (the weft) is wound onto a small bobbin called a “pim” and is inserted into a shuttle this is a device used in weaving to carry the weft thread back and forth between the warp threads.

Weaving fabric in a handloom

Weaving is the process of interlacement of warp and weft (vertical and horizontal) sets of yarn. The foot pedals are pressed to lift the respective heddles according to the weave plan and it has to be in sync with throwing the weft or horizontal yarns across the two sections of warp yarns. Weaving requires immense concentration and physical strength. It takes around 1 day to weave 1 meter of fabric for the throws and cushions in the originalhome collection.

Is your question not covered here?

If you have any questions about our crafts, please do not hesitate to contact us: hello@originalhome.nl.

Other crafts

We celebrate craftsmanship and small scale production. Our products are skilfully handmade by artisans from Indonesia, Bangladesh and Tanzania. They are carefully crafted using traditional skills and simple tools like the hand loom or the spinning wheel.