Did you know that

European sourcing does not always have the smallest footprint

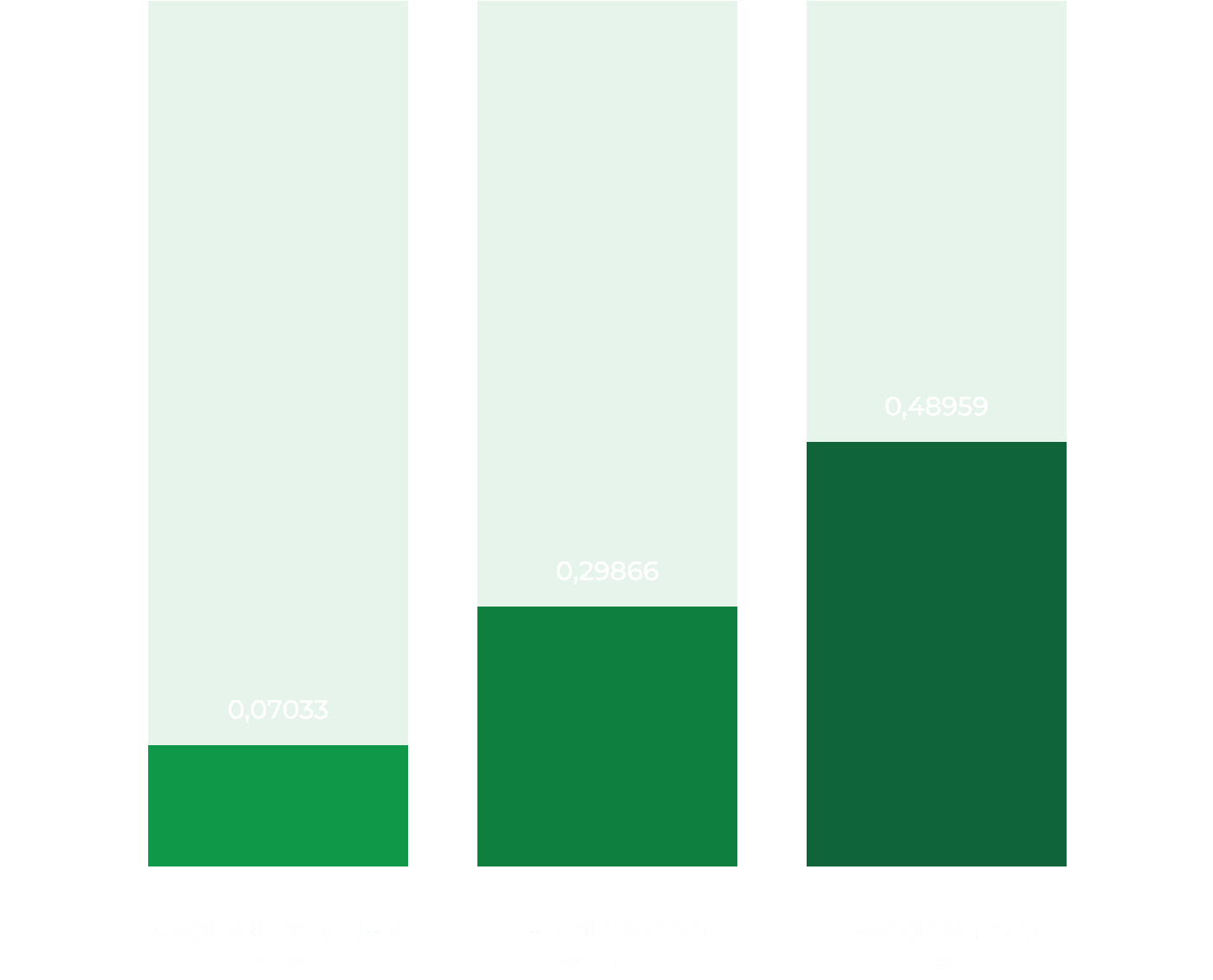

The originalhome drinking glasses, carafes and vases are upcycled, from empty wine bottles in Zanzibar, Tanzania. Zanzibar is far away from the European mainland so it cannot be sustainable, right? Isn’t it better to buy a new glass at your local household store? Wrong! We have calculated the footprint of glass produced e.g. in Germany* and compared it to the footprint of glass produced in China and upcycled glass from Zanzibar. The result of this life cycle assessment is that the upcycled glasses from Zanzibar from originalhome’s collection have the smallest footprint. Even though it travelled hundreds of miles over the sea.

How is this possible?

By reusing glass waste, like empty wine bottles, we prevent it from ending up in end-of-life processes like recycling, burning or landfills. This saves CO2 emissions generated by these processes. This saving is translated into negative emissions of CO2 for the upcycled glasses (<0 kg CO2). Turning empty wine bottles into drinking glasses and carafes is completely executed by hand and requires a tiny amount of electricity. The manual production process has a low impact on the environment. However, the CO2 emissions of transportation from Zanzibar to European mainland is not negligible. The choice for upcycled glass saves CO2, it counterbalances the CO2 emissions of transportation. ( (-) + (+) = small +)

New glass is made from raw materials such as silicon dioxide, calcium carbonate, and sodium carbonate, which need to be burnt at high temperatures (up to 1600°C) to be transformed into glass. The extraction of raw materials plus the energy needed for manufacturing the product has a huge impact on the environment. When you add CO2 emissions of transportation from China to Europe it is clear that importing glass produced in China has a huge effect on the environment ( (+) + (+) = big +)

When you compare this to a glass that is locally made in Europe, e.g. Germany* from new raw materials, it still has a bigger impact on the environment compared to the upcycled glasses from Zanzibar. Although the emissions caused by transportation are limited, the industrial manufacturing process for new glass requires a huge amount of energy which results in a bigger footprint.

Thus, local sourcing is not always the best option to limit the impact on the environment. The way the product is produced and the type of raw material used creates the difference. Upcycled glasses from Zanzibar has the smallest footprint. However, we do not promote import, as the impact can be devastating if the product is industrially manufactured. (see Chinese glass made from new materials).

* Germany is used as an example as it is one of the biggest glass producers in Europe.

This graphic shows the result of the life cycle assessment, which calculates the impact of a product on climate change, measured in kilogram of CO2 equivalent (kg eq CO2). To calculate the carbon footprint, we take into account the entire life cycle, from the extraction of the raw materials to the end-of-life management.

Study conducted by Eco Impact ™